دستگاه الکتروپولیش پارس

Pars Electropolish

The electrolysis process is an electrochemical process based on the surface ionization properties and has advanced technical properties and appearance compared to other polishing methods, which are referred to below in some of these cases.

Most of the mechanical machining systems, to achieve a smooth and glossy surface, crystallize the metal surface, smudges, bends, and fatigue, and sometimes even fails. Electropolishing performs the loading process from the surface by creating a pattern that is completely free from any fatigue and obstruction. In this way, the surface is smooth and often microscopically microscopic. In addition, in many metallic and non-metallic alloys, corrosion resistance and metal deactivation also increase. It processes the metal piece either microscopically or macroscopically. Microscopic polishing brings brilliance and macroscopic polishing to smooth the piece. Pleasure is done sooner because the flow density is higher in the lobes and oxygen protects the holes.

Because the piece is exposed to oxygen, there is no hydrogen tightness in the piece. In fact, electrolysis is a kind of hot and cold without fatigue, which polishes the surface of the unit dehydrogenation.

Another advantage is that the bacterium can not be replicated well on a hydrogen-free surface and an empty line of microscopic scratches. This makes Electropoulos an appropriate choice for use in medicine, pharmaceuticals, semiconductors and food industries, chemical reactors and decorative artifacts, which have a high level of gloss and level of characteristics of the products of these industries. The combination of two features of the lack of directional lines due to mechanical and non-hydrogen-free surface contributes to a completely hygienic surface where no bacteria or contamination can reproduce or accumulate.

Fakhrandish Aria Company announces its bilateral scientific and trade cooperation with Hyteknoloji Company of Turkey in 2018 in the form of exchange of knowledge and experience, as well as providing more and better services to both countries to customers and customers of chemicals and machines. Polishing machines and coating materials in both countries, in order to achieve better and better quality and welfare and access to customers and audiences and ease of access to services for the Middle East as well as customers from both countries. Therefore, to receive information Technical or technical products and technical advice in your country with our business partner in your country We would like to take advantage of our fast and high-quality service in terms of buying advice and receiving samples and technical advice.

Electrostatic immersion dosing device for PARS POLISH M-1 parts and equipment

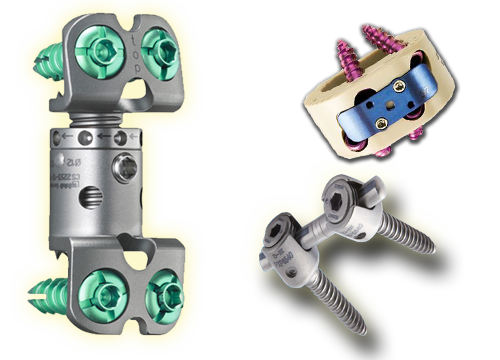

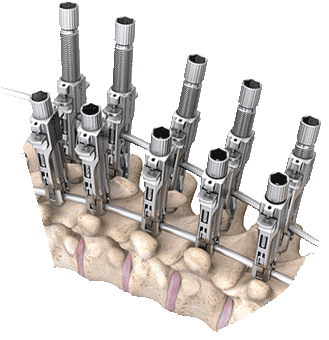

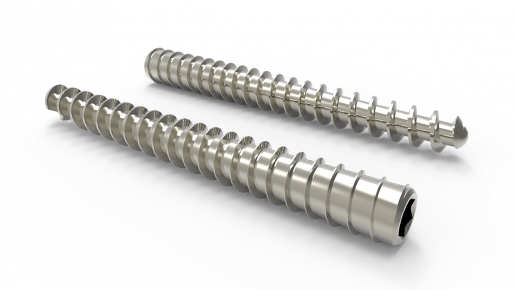

This device is custom-made for use in the manufacture of tools and medical instruments and orthopedic prosthetics

It is also used in decorative and decorative industries as well as in small parts

Until medium is usable and exploitable, also due to the knowledge base of the design process and

Manufacturing and manufacturing of this kind of machinery in this company, designing and manufacturing of this type of machinery and electrolyte

The corresponding consumption in the process is possible for parts in large and small volumes and in various alloys.

The EP-100 Electro-Pulse Pars is inexpensive and weighs very low, which is easy to carry and with various torches, such as corner turret, brush torch, etc., and eliminates your need for a versatile electro-pulp. This version of the device is suitable for temporary work and large-scale work, and for workshops with a low number of works, and there are not many capabilities, and only because of the observance of the right of consumers on small and small scale, the number of directions for semi-professionals or applications A case is suggested to customers. Use LDA for professional or higher work efficiency than other models of its manufacturing units. (Engineering Unit of Fakhrandish Arya Company)

This device has all accessories and accessories including:

– Brush or pad device (to customer’s choice)

– Gloves and safety glasses

-The electrolyte solution

Protective foam

– Clamp and connector nipple

DVD and educational device

– For warranty and machine manual

And……

فارسی

فارسی  English

English