لایه نشانی و پوشش دهی فلزات توسط قوس پلاسما

PEO Plasma Electrolytic Oxidation

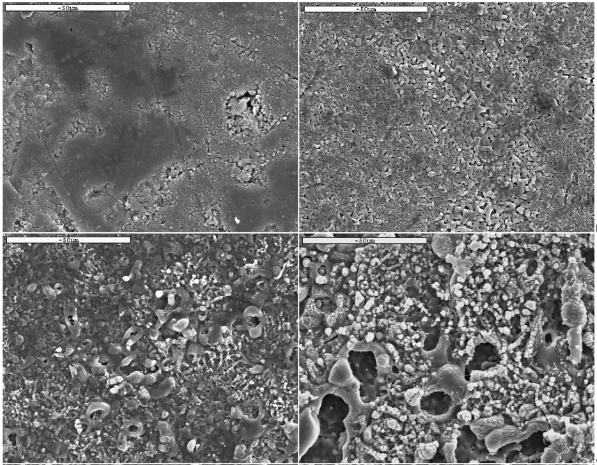

شرکت فخراندیش آریا با توجه به ماهیت نوین بودن این دانش و تکنولوژی در جهان و جایگاه بالای تکنیکی فرآیند و تکنیک PEO و جایگاه خاص این تکنیک در صنایع نوین و پیشرفته و نیز امکانات و تجربیات موجود در بستر شرکت از سال ۱۳۹۱ پیرامون هماهنگی و همکاری متقابل با تعدادی از دانش آموختگان و دانشجویان مراکز دانشگاهی اقدام به طراحی و ساخت سیستم و دستگاههای مربوطه را در دست کار قرار داده است و تا کنون توانسته است بصورت آزمایشگاهی و صنعتی به پاره ای از ارگانها و شرکتهای متقاضی این تکنولوژی ارائه خدمات داشته باشد که در اینجا مختصری از نحوه کار این سیستم و فرآیند و نیر تصاویری از نمونه های انجان شده و پوشش شده با این روش قرار دارد جهت هرگونه اطلاعات تکمیلی تر و یا نیاز به خدمات ساخت و مشاوره ای در این زمینه لطفا با مهندسین بخش فنی این شرکت مکاتبه فرمائید (فلرات و آلیاژهای گروه های استینلس استیل و آلومنیوم و منیزیم تا کنون جزو موارد کاری و تحقیقاتی این مجموعه قرارداشته است)

کلیات فرآیند PEO

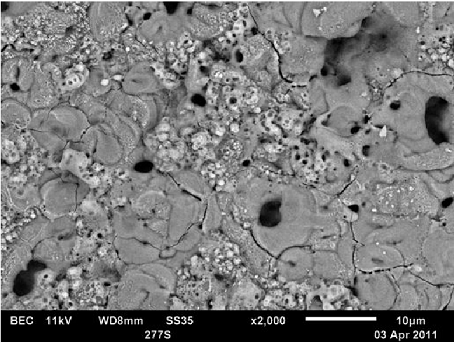

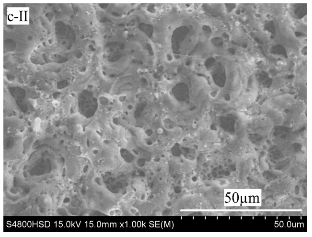

تشکیل PEO برروی سطوح شامل تشکیل لایه سرامیکی با خواص بهبود یافته با ضخامت ۱۰ تا چند صد میکرون می باشد. پوشش اکسیدی با پلاریزاسیون در ولتاژهای بالا در یک الکترولیت غیر خورنده بوجود می آید که در آن در یک ولتاژ خاص اسپارک های الکتریکی آغاز شده و یونیزاسیون حرارتی بهمراه تخلیه شارژی اتفاق می افتد. لایه اکسیدی می تواند همراه با عناصر موجود در الکترولیت ذوب شود.PEO می تواند بصورت موضعی در کانال های تخلیه که فشار و دما بالاست اتفاق بیافتد. لایه اکسیدی تشکیل شده در بالا معمولا متخلخل بوده، لایه میانی چگال و فشرده می باشد و لایه زیرین نیز نازک ترین لایه است.

خواص سطحی ناشی از اعمال روش پوشش دهی PEO

- ایجاد پوشش های سخت و چگال

- چسبندگی زیادی به زیرلایه ها و فلز پایه

- مقاومت به سایش و خوردگی بالا

- ایجاد مقاومت حرارتی بالادر لایه سطحی فلز

- بالا بردن ضریب دی الکتریک سطوح مواد

عوامل موثر در فرآیند PEO

- جنس زیر لایه

- الکترولیت

- پارامترهای الکتریکی

- دما

- زمان اکسیداسیون

- مواد افزودنی

فارسی

فارسی  English

English