فلاکس فعال ساز جوش جهت فرآیندهای جوشکاری

ACTIVATOR WELDING FLUX

(TIG-MIG/MAG-SAW-LASER WELDING )

ATIG -ACTIVE FLUX FOR WELDING

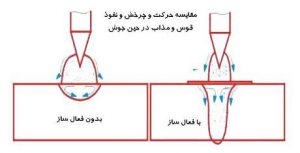

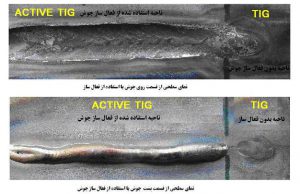

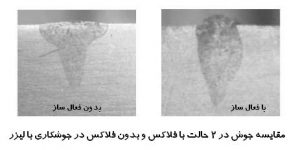

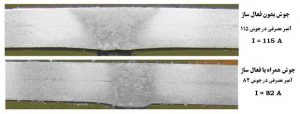

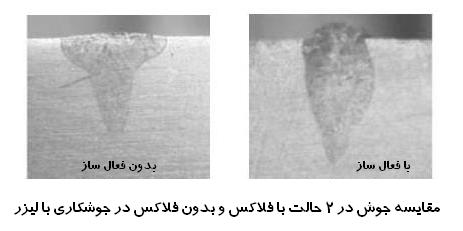

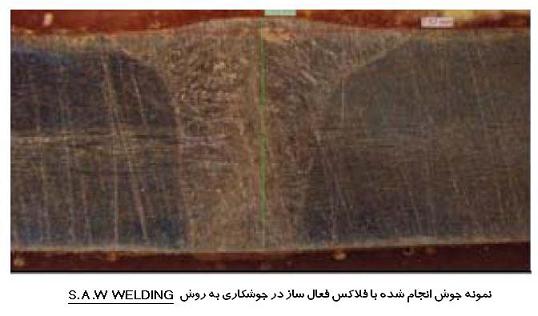

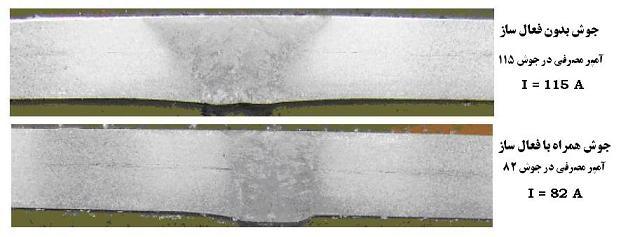

The aforementioned product based on the chemical fusion and raising the kinetic energy at the site of the boiling pond on the one hand causes more penetration (at least 2.5 times more) and, on the other hand, reduces the amount of ampere consumption (at least 30% less In the welding process and, in other words, increases the desired properties of the weld, and the perfect combination of the alloy in the boiling point between the base metal and the metal is boiled. Also, with intense molecular activity in the boiling pond, all existing defects are eliminated In the common area between metal and base metal (HAZ), one of the other benefits of using this product is the need for action It is a pre-welding method in ordinary welds with a low amount of penetration and buckling, and the other advantage of using this product is that it does not cause distortion and deformation in the base metal and work piece due to the lowering of the inlet temperature (due to the dropping of the amperage Consumption to the welding site and defective workpiece, such as changes in the base metal crystalline network, has been significantly reduced, which does not alter or maintain the mechanical properties of the metal and base alloy.

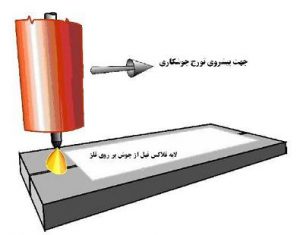

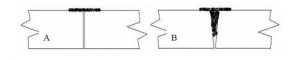

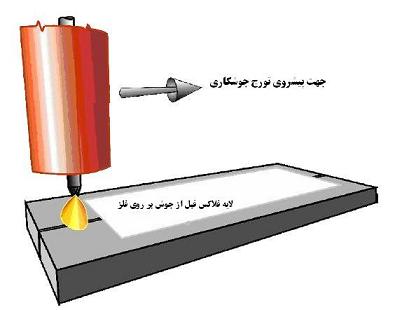

The product has been produced in 3 groups A, B, C, respectively. Group A is for vertical and deep penetration in the wool root, and group B for penetration in the base metal and horizontal, and the combined group C from the two cases mentioned above This means increasing the relative penetration in the root and also in the side of the weld. The use of the above-mentioned emulsion solution is such that, in the weld seam, before welding with a brush or a spray mechanism or other method Can be immersed in a thin layer (at least 0.3 mm thick) of the solution on the surface of the metal, and after 2 minutes the solution is dried and ready to go. It’s hurt.

For further information, it is worth noting that at present, in most advanced European and American countries, this material is used in the process of production and welding of marine, military, nuclear, air and rail industries, as well as large industrial and construction metal structures, power plants and transmission pipes It is used for the first time in our country, Iran. This company has succeeded in producing and presenting this product in different groups, with the possibility of defining and presenting the formula for type and amount of penetration for all types of carbon steel, stainless steel and aluminum alloys, and Titanium has fallen.

فارسی

فارسی  English

English