WPS & PQR

Providing a variety of procedures for the implementation and control of processes before and after welding to achieve the best result in terms of mechanical, chemical and physical properties of a simple seam joint is important in the industry, which unfortunately in some cases it is seen that sensitive parts or above Sensitive, regardless of the procedures required to perform a proper and safe welding seam, are considered as an elementary and simple piece, and after a short period of time, the result of a lack of a futuristic prediction of future segmentation and the need to The procedure is used for that boiling gripper, which is fracture, tear or leak or longitudinal cracks And the transverse in the same weld is apparently simple

It is therefore pointed out that at a boiling point obviously simple and insignificant cases are many technical and metallurgical points that are hidden from the viewpoint of many individuals and that, in all internal and international standards, this is the case of procedures The welding process is used in the above processes. A lot of emphasis has been put on

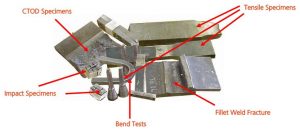

Fakhrandish Arya Co., based on the knowledge and science of welding, as well as various experiences in this industry to provide a variety of performance and control procedures (WPS / PQR) for a variety of iron and steel base alloys such as carbon steel, stainless steel, aluminum, titanium, copper , Chrome and Nickel, Monel and Inconel and other super alloys are able to provide a variety of above-mentioned procedures.

Several examples of predefined forms of welding procedures and their routine to get

WPS1 WPS2 WPS3 WPS4 PQR1 PQR2 PQR3

فارسی

فارسی  English

English